MAICOPRESSE

Machines and automation systems

for die-casting and plastic injection moulding

Over 50 years of experience and flexibility to the service of our clients.

We have built our reputation with over 50 years of tireless pursuit of excellence in all aspects of our job, from technologies to materials, from components to processing, from assembly to customer service, to establish what we value most: a long-lasting relationship of trust and respect with our clients.

Machines and accessories for die-casting and injection moulding of plastic materials: highly efficient, technologically advanced machinery for uncompromising quality.

Industrial automation and robotic systems for die-casting and plastic sector: innovative and high-quality automation systems to optimize production processes.

OUR NEWS

We present our new line of unique, medium/large-tonnage ELECTRIC plastic injection moulding machines. High energy savings combined with the usual reliability of our machines. Read more >>>

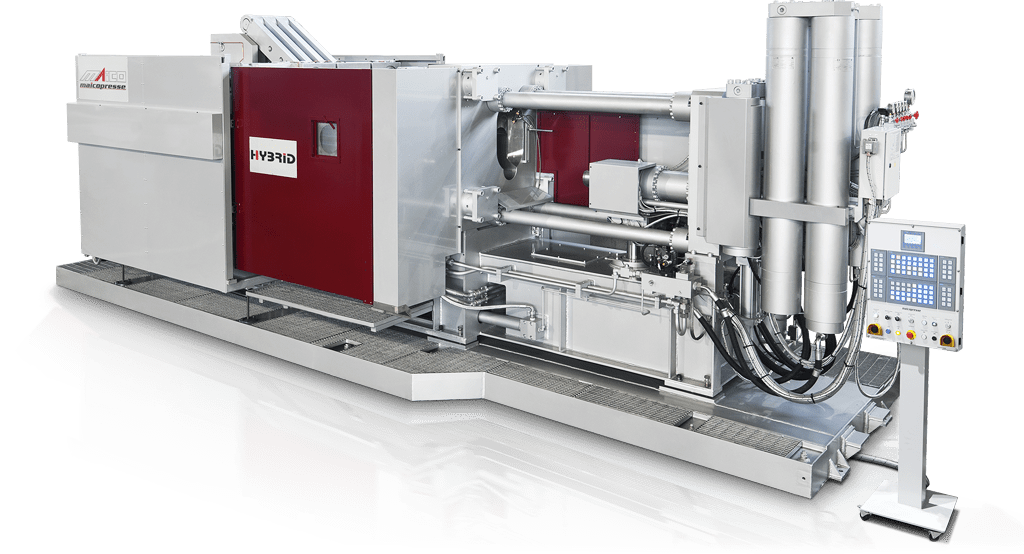

Die-casting machine GK 1650 HYBRID complete with servo auto ladle made by IROBI.

Watch the video to know the advantages of our machines with HYBRID technology and see some of our patented applications.

Saving energy, no cooling water needed, less hydraulic fluids, high productivity, speed and precision and also patented clamping unit, platens made by forged stainless steel, automatic nitrogen pressure compensator.

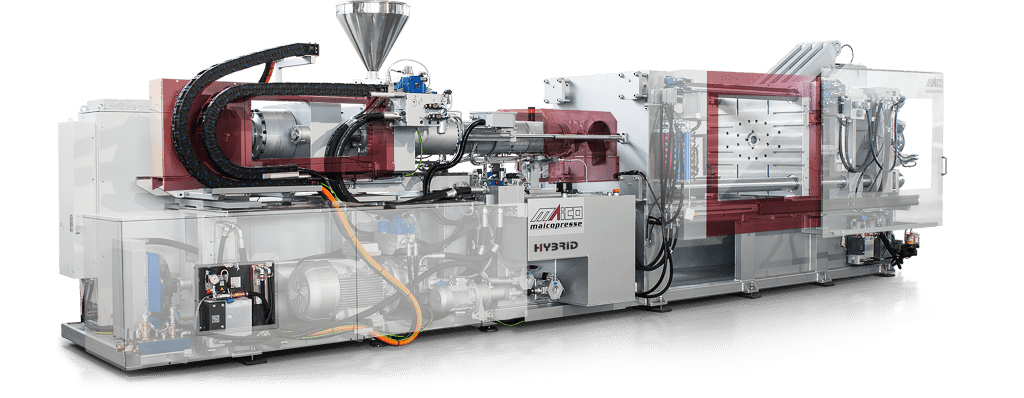

Large tonnage plastic injection machines: HYDRO 5000 Ton e MB 4000 Ton.

We introduce you our injection moulding machines HYDRO 5000 Ton and MB 4000 Ton where power and efficiency meet. With this video we want focus the attention on the key characteristics of our big tonnage injection moulding machines.

Power, strong, reliability, precision, saving energy, efficiency, high technology, fast cycles, susteinability, innovation, these are just some of the strenghts of our injection moulding machines.

SINCE 1975

MANUFACTURERS

OF DIE-CASTING AND INJECTION MOULDING MACHINES.

We tirelessly pursue innovation and sustainability to develop avant-garde technologies and offer solutions to various difficulties regarding the world of die-casting and injection moulding.

Strong of a series of international patents and of a true vocation for custom-made projects, we work shoulder-to-shoulder with numerous prestigious companies and holdings, in order to offer ever improving products that give a true competitive advantage to our Customers. Furthermore, we project and execute whole working cells, complete with fully customised, integrated automation systems.

DIE-CASTING

Die-casting machines for light alloys and automated working cells with customised

peripheral devices

PLASTICS

Injection moulding machines for plastics and automated working cells

with customised peripheral devices

SERVICES

Technical assistance, revamping and updates,

spare parts and selling of refurbished second hand machines.

AUTOMATION SYSTEMS

Peripheral devices, automated working cells

and customised projects

DIE-CASTING

MACHINES FOR LIGHT ALLOYS

PLASTIC INJECTION

MOULDING MACHINES

WHAT SETS US APART

A COMPLETE SERVICE FROM MECHANICAL DESIGN TO CUSTOMER CARE

A complete services,

FROM MECHANICAL DESIGN TO CUSTOMER CARE

CUSTOMER CARE

01. ON-SITE TECHNICAL SUPPORT

Our efficient and responsive team of skilled technicians intervenes within 24 hours nationally and in Europe,

and within 48 hours of request in the rest of the World.

02. TELESERVICE AND PHONE ASSISTANCE

Remote teleservice assistance thanks to real-time connection to our machines

and around the clock telephone support.

03. SPARES

Our automated vertical storage is continuously stocked,

to ensure quick delivery of maintenance parts.

AUTOMATION

MAICOPRESSE S.P.A.

AUTOMATION SYSTEM

In order to offer a complete service and meet all production requirements of our clients, IROBI S.r.l. was established in 1985 as Maicopresse sister company specializing in industrial automation.

In 2025, Irobi S.r.l. was merged into Maicopresse S.p.A., becoming its division specialising in automation for improved service efficiency.

The automation division of Maicopresse S.p.A. develops, designs and manufactures:

- Ladles

- Spray robots and spray heads

- Anthropomorphic and cartesian robots

- Complete integrated automation systems (working cells) for die-casting and injection moulding machines.

It has quickly established itself in the fields of robotics and automation, thanks to its pioneering choices and to the efficiency and flexibility of its devices.

LATEST NEWS

MAICOPRESSE

We present our new line of unique, medium/large-tonnage ELECTRIC plastic injection moulding machines. High energy savings combined with the usual reliability of our machines. Read more >>>

From 19th to 21st of September 2024 we will attend you! Come to visit us at our stand H6-C105

From 18th to 21st of June we will attend FENAF 2024 Exhibition. Meet us at ITALIAN PAVILLON – BOOTH B05.